ATOS ScanBox Series 6

In production metrology, it is important to check a large number of parts as completely as possible, in order to be able to correct faulty production processes at short notice and in a targeted manner.

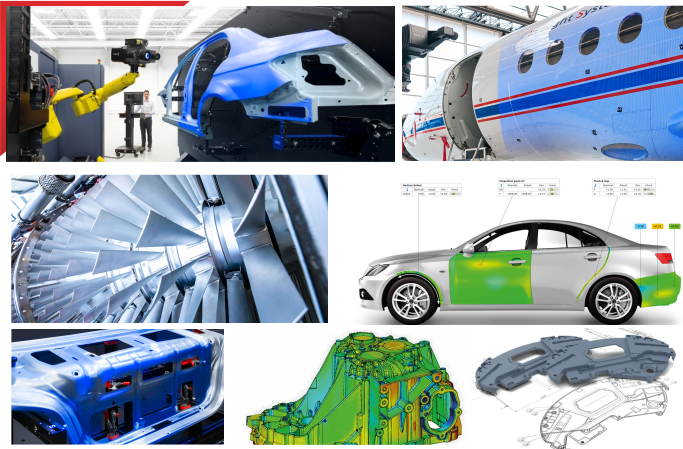

Typical applications for the ATOS ScanBox 6130 are quality control e.g. of attached parts or interior parts, but also product development and tool tryout. Very large or heavy parts can also be measured in the ATOS ScanBox 6130, for example cast parts or tools.

In production metrology, it is important to check a large number of parts as completely as possible, in order to be able to correct faulty production processes at short notice and in a targeted manner.

Typical applications for the ATOS ScanBox 6130 are quality control e.g. of attached parts or interior parts, but also product development and tool tryout. Very large or heavy parts can also be measured in the ATOS ScanBox 6130, for example cast parts or tools.

Pallet System

The components and the fixtures can be set up outside the ATOS ScanBox on changing pallets. The pallets are loaded quickly and reproducibly using positioning pins. This results in a high throughput of parts and is ideally suited for series production.

Quick Loading and Unloading

Measuring 3.1 m, the entry of the ATOS ScanBox 6130 is very wide and is secured by a safety light sensor. This allows an uncomplicated use of loading tools such as cranes, forklift trucks or pallet trucks in order to be able to place large parts on the measurement machine.

Full-Field Trend Analysis

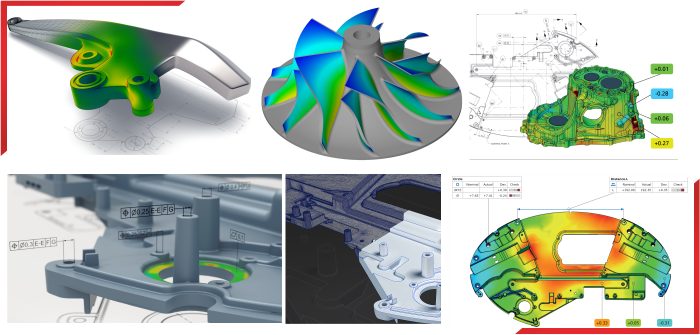

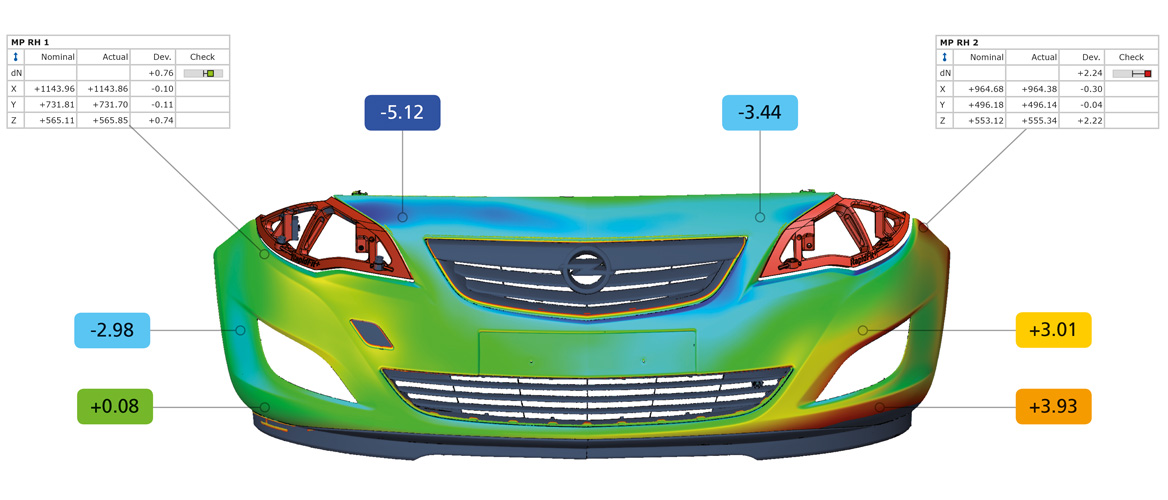

For the verification of components, the full-field data can be analyzed (visualization of deviations, hemmed edges, radii, inspection sections, …). Further measurements of other parts enable completely virtual installations. In the case of inspections during production, all the inspection characteristics and functional dimensions are recorded. These are transferred to the statistical process control systems and presented as trend analyses.

© 2022. APM Technologies 3D Pvt Ltd

Copyright © 2022. All rights reserved