Plastics & Injection Molding

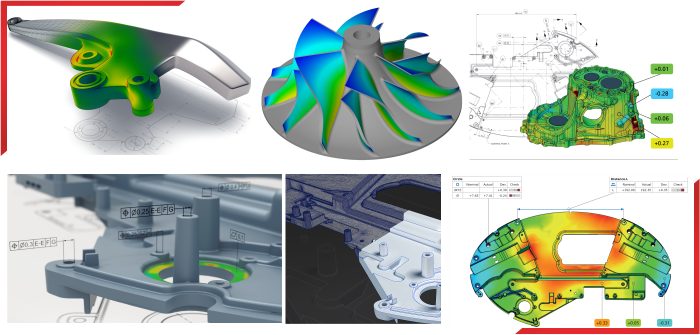

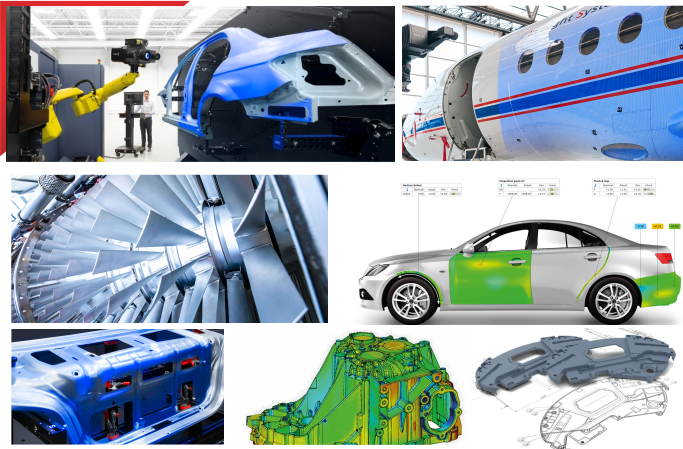

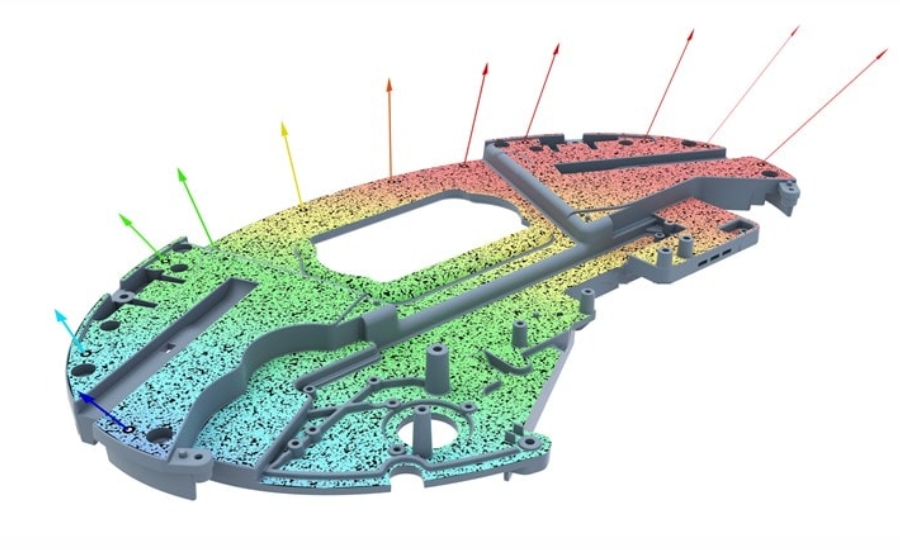

In plastics engineering, 3D metrology supports and speeds up all phases in injection molding, blow molding and thermoforming processes: from prototype & tool construction to first article inspection reports up to assembly analysis and load testing.

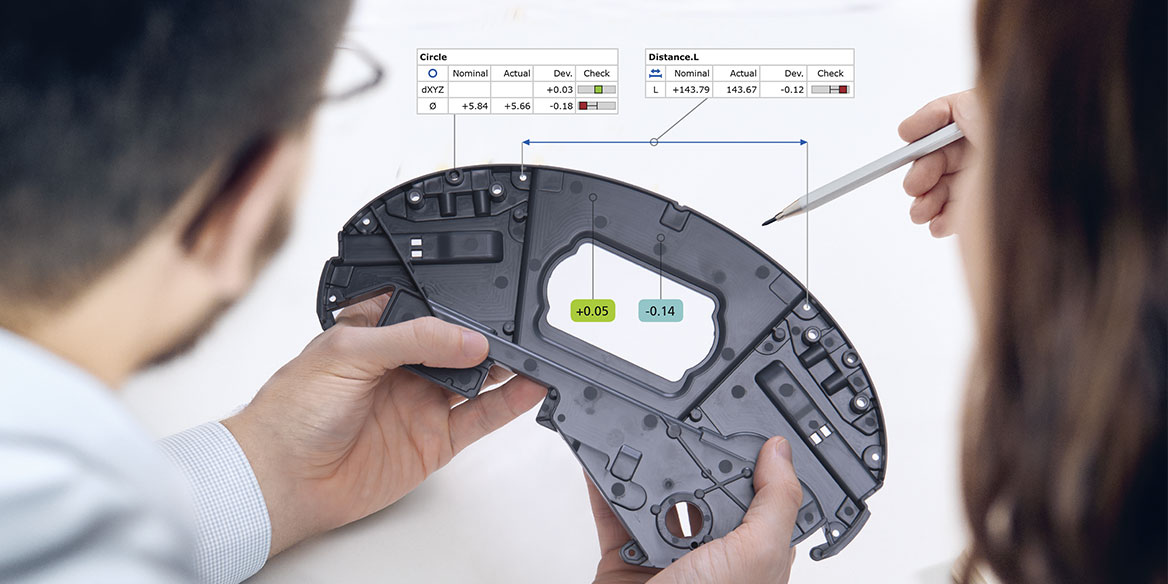

ATOS is an optical 3D coordinate measuring system allowing non-contact measurements of complete surfaces of prototypes, electrodes, tools and injection molded parts regardless of the object size. In contrast to tactile measuring techniques, this method even captures complex freeform contours quickly and completely.

Plastic & Injection Molding Process Chains

Full-field surface measurements guarantee a faster first article inspection and targeted tool correction, thereby reducing production lead times. For the production-accompanying quality control, both the measurements and the entire evaluation process can be automated.

3D Metrology for Injection Molding, Blow Molding and Thermoforming Processes

Material Properties

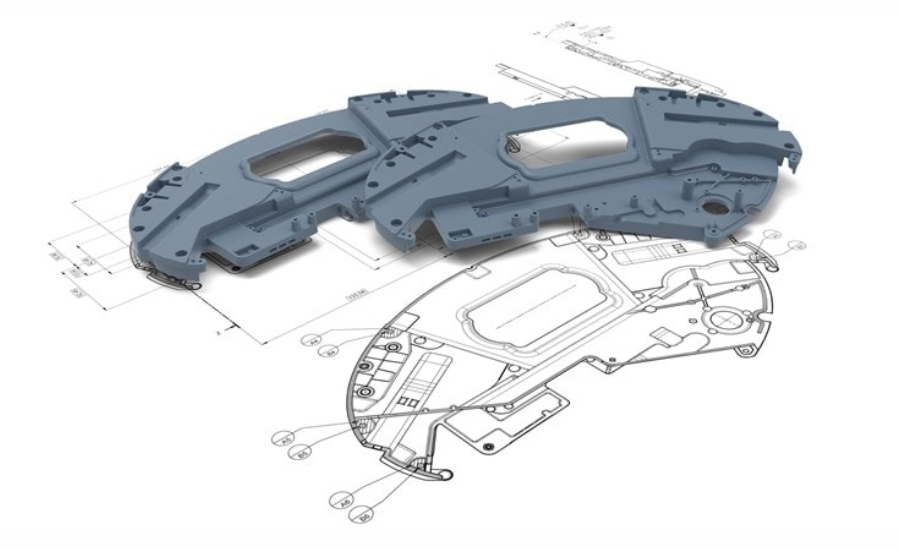

Part Design (CAD/PMI)

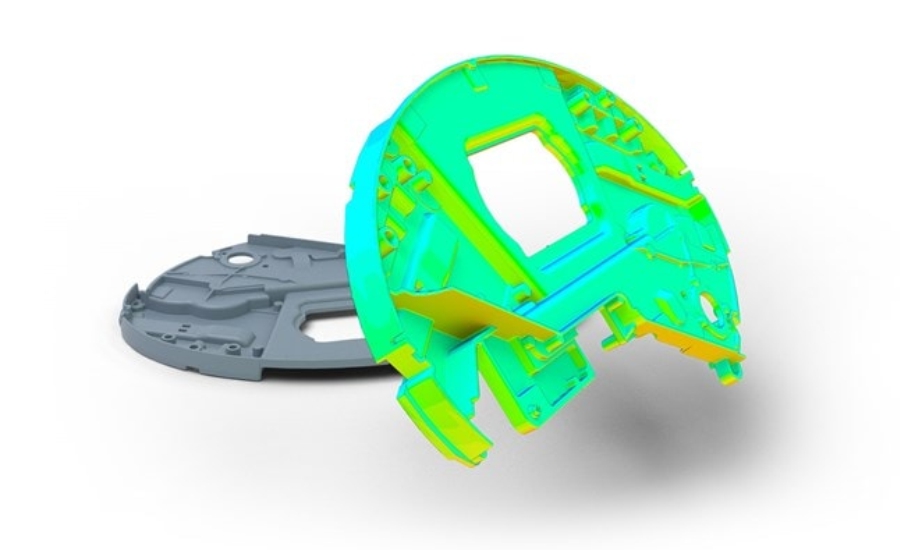

Simulation and Validation (CAE)

Tools and Electrodes (CAD/CAM)

Plastic Parts and First Article Inspection

Production and Series Inspection

Assembly and Load Tests

© 2022. APM Technologies 3D Pvt Ltd

Copyright © 2022. All rights reserved