Highlight

A powerful 3D scanner

Feature

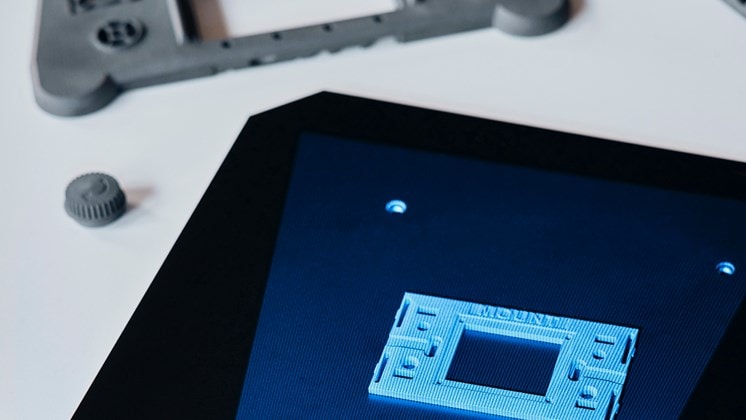

Chooose your measuring volume

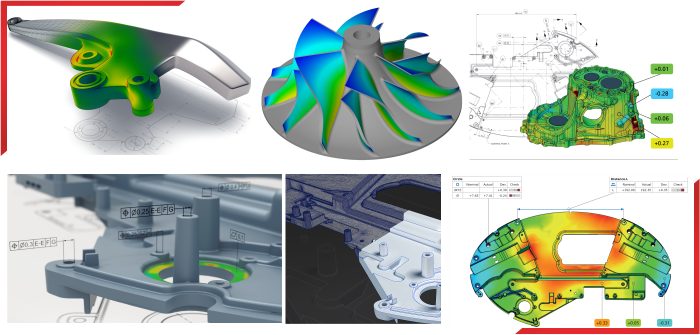

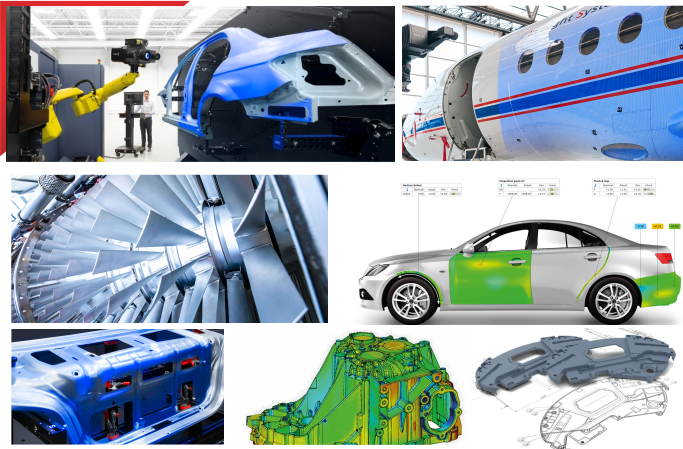

Applications

Capture and create

Acceseries

Tools to support you

VIDEO

Choose your measuring volume

Due to the stereo camera principle, the sensor recognizes changing ambient conditions during operation and can compensate for these changes. To ensure the quality of the measuring data, the software of the sensor continuously monitors the sensor status.

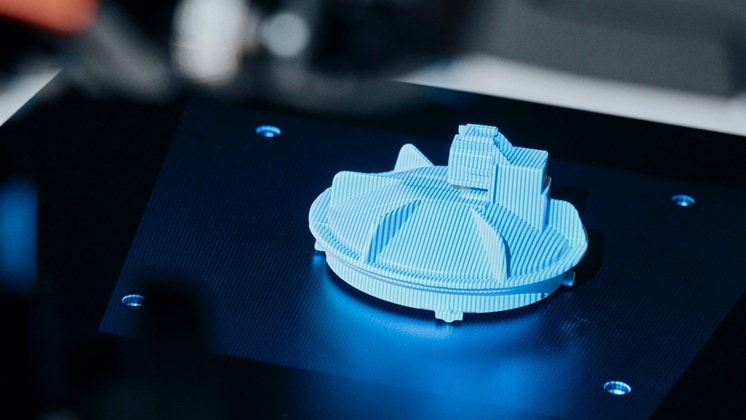

Get there fast with fringe projection

Due to the stereo camera principle, the sensor recognizes changing ambient conditions during operation and can compensate for these changes. To ensure the quality of the measuring data, the software of the sensor continuously monitors the sensor status.

A self monitoring system for real life issues

Due to the stereo camera principle, the sensor recognizes changing ambient conditions during operation and can compensate for these changes. To ensure the quality of the measuring data, the software of the sensor continuously monitors the sensor status.

Precision in all lighting conditions: GOM’s Blue Light Technology

Due to the stereo camera principle, the sensor recognizes changing ambient conditions during operation and can compensate for these changes. To ensure the quality of the measuring data, the software of the sensor continuously monitors the sensor status.

© 2022. APM Technologies 3D Pvt Ltd

Copyright © 2022. All rights reserved