What Could You Print?

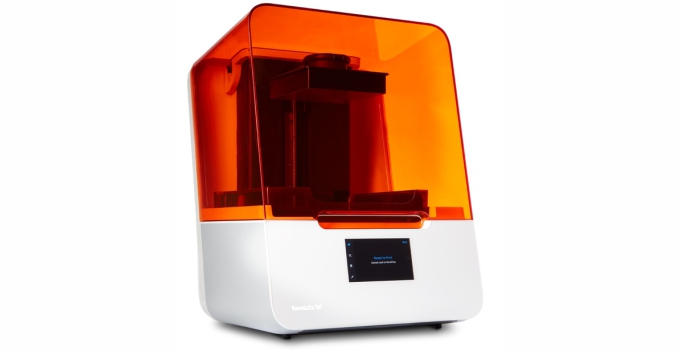

form3B+ for Healthcare

Implantology Model

Splenic Artery

Femur Ball and Socket

Laryngoscope

Foot

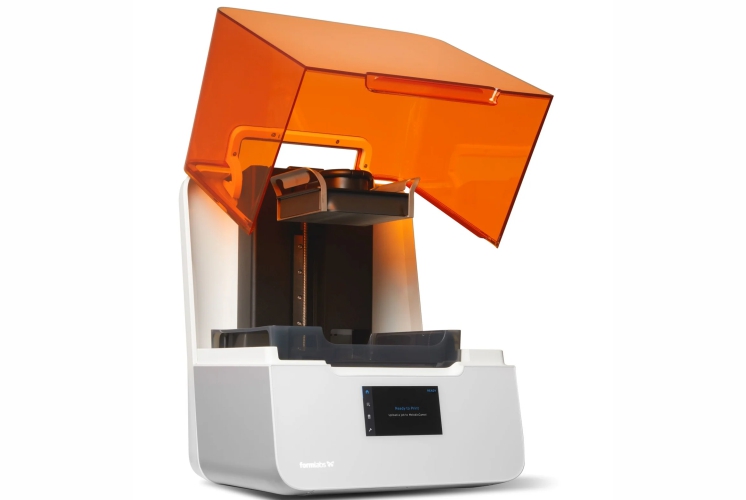

The Form 3B+ Workflow

Design

Wash

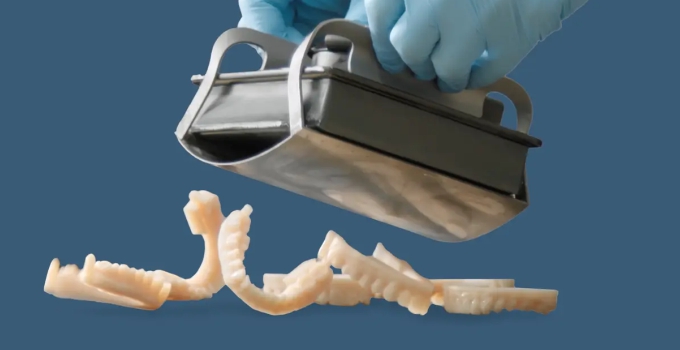

Remove Part

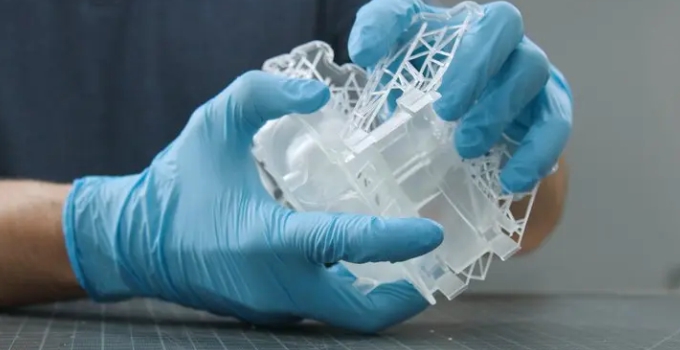

Remove Support

Cure

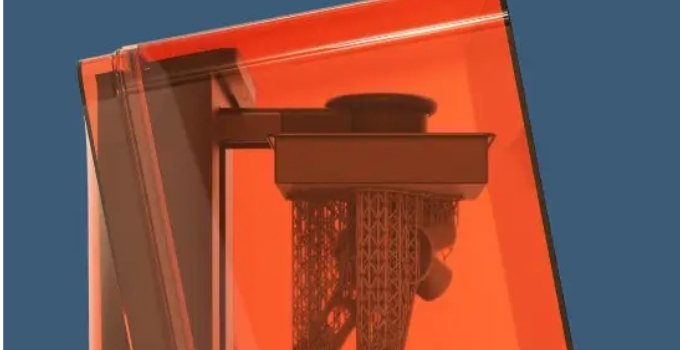

Quick Release Technology

Enhanced Light Touch Supports

Achieve a Flawless Finish

© 2023. APM Technologies 3D Pvt Ltd

Copyright © 2023. All rights reserved