Customer login

Not registered yet?

Register now! It is easy and done in 1 minute and gives you access to special discounts and much more!

3D Printers - Formlabs

- Home

- Product

- 3D Printers

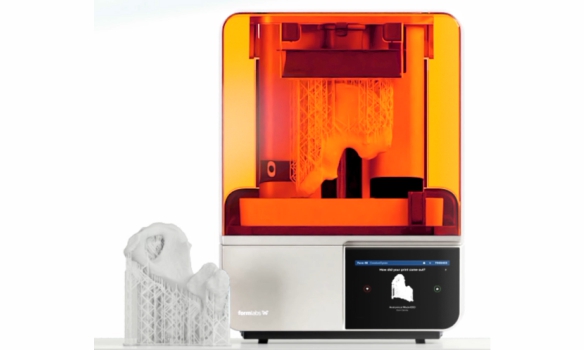

Form 4

Form 4

Form 4

Blazing Speed Meets Industrial Production

Turn your ideas into reality faster than ever with easy workflows, leading reliability, and stunning part quality using the Form 4 resin 3D printer ecosystem. Form 4 is a blazing fast masked SLA 3D printer that combines an industry-leading materials library with a reliable, accurate print engine. With tight tolerances, parts printed in every resin on Form 4 will match your design parameters, every time.

More

Form 4 Ideal for:

Rapid prototyping and production

Patterns for molds and casting

Rapid tooling and manufacturing aids

Model making

Form 4B

Blazing Speed Meets Surgical Precision

Create biocompatible, sterilizable anatomical models and medical devices fast, with easy workflows, leading reliability, versatile materials, and stunning part quality using Form 4B, a blazing fast resin 3D printer that offers the most diverse materials library for healthcare.

More

Form 4B Ideal for:

Small and medium parts requiring biocompatibility and sterilization compatibility

Medical device prototypes, jigs, fixtures, molds, and end-use parts

Patient-specific anatomical models and surgical instruments

Surgical planning models for diagnostic use in FDA-cleared workflows

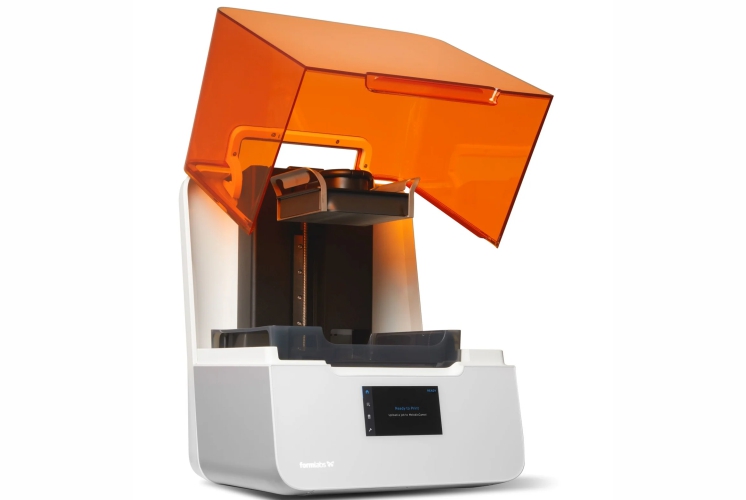

Our Go-To Affordable, Industrial-Quality Desktop 3D Printer

Produce functional, high-quality prototypes and end-use parts in record time with the Form 3+, an affordable, industrial-quality 3D printer that consistently delivers. The Form 3+ offers reliable print quality and accuracy, easy setup and maintenance, and a wide range of high-performance materials.

More

Form 3+ Ideal for:

Rapid prototyping and production

Patterns for molds and casting

Rapid tooling and manufacturing aids

Model making

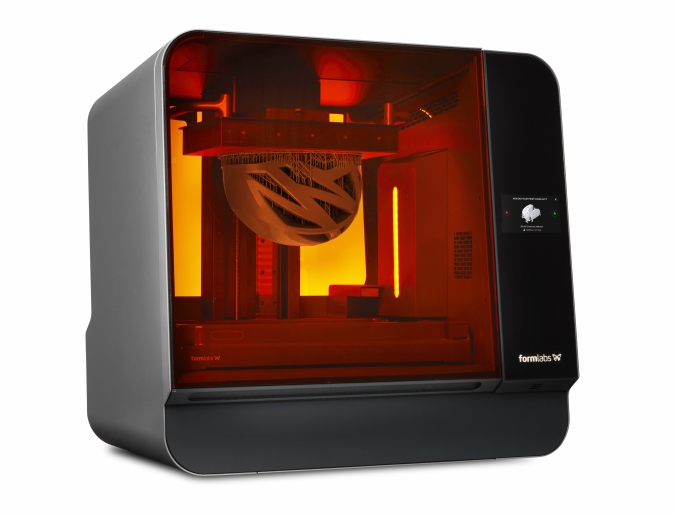

Form 3L

A Large Format 3D Printer That Reliably Brings Full-Scale Ideas To Life

Take control of large-format part production and bring your biggest ideas to life with the Form 3L, a cost-effective large-format 3D printer that doesn’t compromise on the details.

Form 3L Ideal for:

Full-size rapid prototyping

Rapid tooling and manufacturing aids

Large-scale models

Form 3B+

An Advanced Desktop 3D Printer Designed for Healthcare

Rapidly print patient-specific parts at the point of care and bring innovative R&D and commercial production in-house with the Form 3B+, an advanced 3D printer for healthcare professionals and medical device engineers. The Form 3B+ is compatible with our entire SLA materials library, including biocompatible, sterilizable materials.

Form 3B+ Ideal for:

Small and medium parts requiring biocompatibility and sterilization compatibility

Visual aids for diagnosis and education

Medical device prototypes, jigs, fixtures, molds, and end-use parts

Surgical planning models for diagnostic use in FDA-cleared workflows

Patient-specific anatomical models and surgical instruments

Form 3BL

A Large Format 3D Printer Developed for Healthcare

3D print adult patient-specific anatomy at full, 1:1 scale or large medical devices with the Form 3BL, a large-format medical 3D printer compatible with the majority of our SLA materials, including biocompatible, sterilizable resins made in our ISO 13485 certified, FDA-registered facility.

Form 3BL Ideal for:

Large parts requiring biocompatibility and sterilization compatibility

Surgeon-specific or patient-specific surgical tools

Full-size, anatomical models at 1:1 scale, including pediatric and adult anatomy

Surgical planning models for diagnostic use in FDA-cleared workflows

Medical device prototypes, jigs, fixtures, assemblies, and end-use parts

Fuse 1+ 30W

Truly Rapid SLS, For High-Performance Parts Within 24 Hours

Designed for maximum output and minimum waste, Fuse 1+ 30W is our compact SLS 3D printer that packs an industrial punch. Unlock unprecedented print speeds and material enablement to deliver truly rapid production in-house. From print setup to powder recovery, our easy-to-use hardware and software are designed to maximize your efficiency at every step of the process.

Fuse 1+ 30W Ideal for:

High-speed printing for maximum throughput and fast turnaround

Rapid prototyping and production of industrial-grade, end-use parts

In-house manufacturing with complete design freedom

Ready-to-use, patient-specific, and biocompatible medical devices

© 2022. APM Technologies 3D Pvt Ltd

Copyright © 2022. All rights reserved