Customer login

Not registered yet?

Register now! It is easy and done in 1 minute and gives you access to special discounts and much more!

ARGUS

- Home

- Products

- ARGUS

ARGUS – Optical Forming Analysis

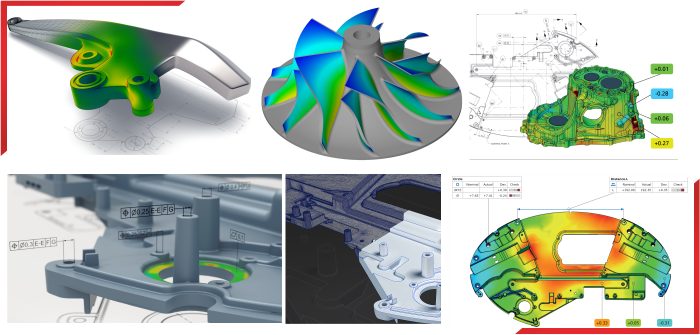

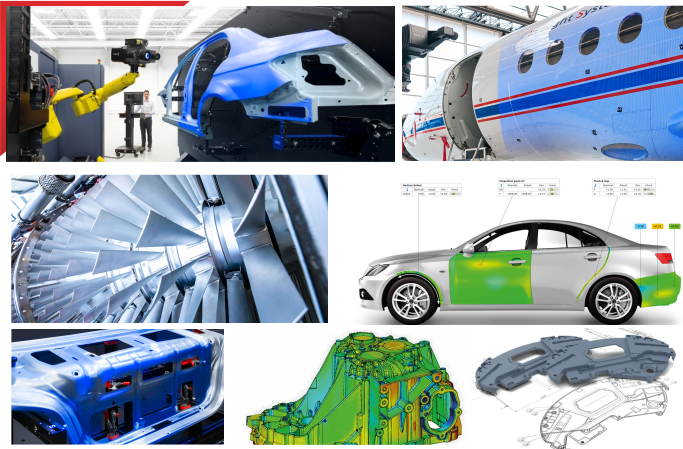

The forming analysis system ARGUS supports the optimization of the sheet metal forming process taking into account the correct material selection and the optimization of tools. This a decisive factor for competitiveness, particularly in the automotive industry.

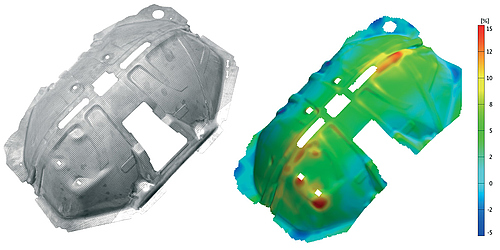

ARGUS provides full-field results with high local resolution for small as well as for large components. Therefore, it is ideal for numerous sheet metal forming tasks like: detection of critical deformation areas, solving complex forming problems, optimization of forming processes, verification of tools as well as verification and optimization of numerical simulations.

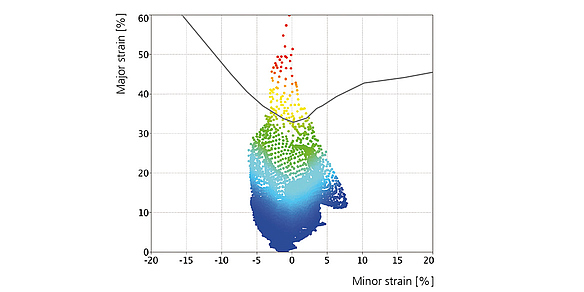

Furthermore the measurement system delivers full-field results for the verification of numerical forming simulations. The results from the ARGUS system provide full-field information about: 3D coordinates of the component‘s surface, Form change (major and minor strain, thickness reduction, Forming Limit Diagram (FLD) and sheet metal hardening.

ARGUS supports optimization processes in sheet metal forming by means

The optical forming analysis with ARGUS provides for