Customer login

Not registered yet?

Register now! It is easy and done in 1 minute and gives you access to special discounts and much more!

Figure 4 Modular

- Home

- Product

- Figure 4 Modular

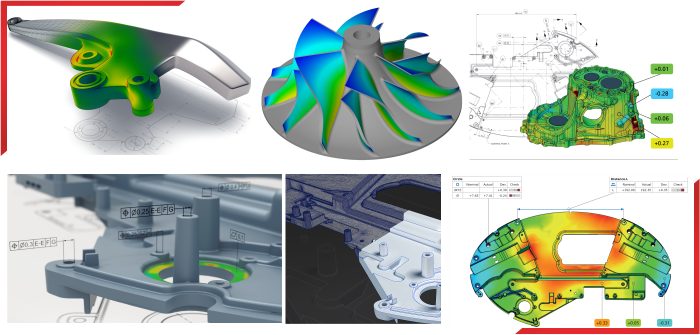

Figure 4 Technology

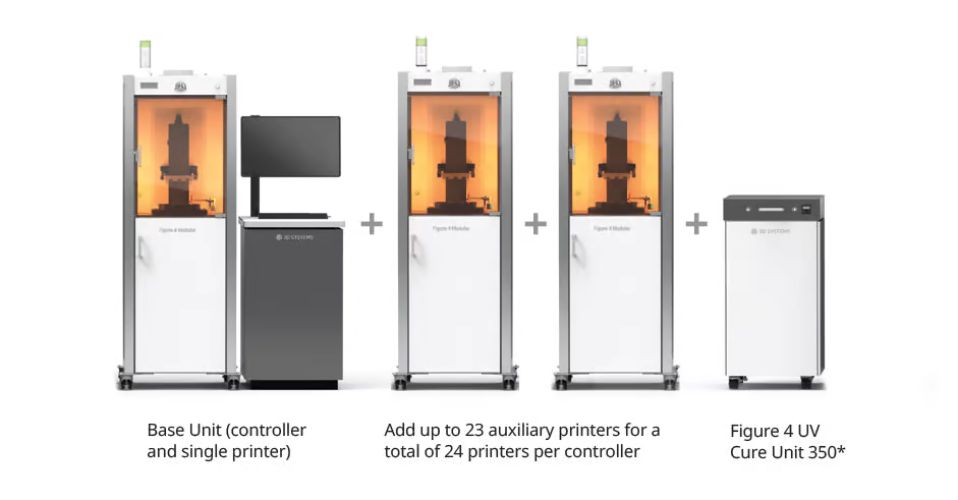

Figure 4® Modular is a scalable, semi-automated 3D production solution that grows with your business, enabling capacity to meet your present and future needs, up to 10,000 parts per month, for unprecedented manufacturing agility. With expandable capacity up to 24 print engines, automated job management and queuing, automated material delivery, and centralized post-processing, Figure 4 Modular’s end-to-end digital manufacturing workflow is ideal for low to mid-volume production and bridge manufacturing. In addition, each printer can run different materials and different jobs as part of a single high throughput line serving a multitude of parts being produced.

FIGURE 4 Modular

Modular Scalability

Figure 4 Modular's individual printers enable simultaneous production of a wide variety of part sizes and shapes, in multiple materials for a diverse range of parts for production and prototyping.

Low Total Cost of Operations

Figure 4 Modular enables companies to move directly into manufacturing from a digital CAD file, bypassing tooling costs and delays to start delivering final parts immediately. This semi-automated solution reduces labor through automated job management and queuing, and an automated material feed system. .

Unparalleled Flexibility

Figure 4 Modular's individual printers enable simultaneous production of a wide variety of part sizes and shapes, in multiple materials for a diverse range of parts for production and prototyping.

End-to-End Productivity

Fast and easy print jobs preparation, ultra-fast print speeds, post-curing in minutes instead of hours and production management ensure high parts throughput with high accuracy and repeatability.

Broad Range of Materials

3D Systems' Material Design Center has over 30 years of proven R&D experience and process development expertise. The broad and expanding range of materials available for Figure 4 Modular addresses a wide variety of applications needs, for functional prototyping, direct production of end-use parts, molding and casting, and includes rigid and durable thermoplastic-like, rubber-like, heat resistant and biocompatible capable materials.

Printer Hardware

Build Volume (xyz): 124.8 x 70.2 x 346 mm (4.9 x 2.8 x 13.6 in)

Minimum Layer Thickness : 0.01 mm (0.0004 in)

Resolution 1920 x 1080 pixel

Pixel Pitch : 65 microns (0.0025 in) (390.8 effective PPI)

Wavelength : 405 nm

Operating Environment Temperature Humidity (RH) : 24/7 operation 5-30 °C (41-86 °F) 30-70%

Electrical: 100-240 VAC, 50/60 Hz, Single Phase, 15A/7.5A

Compressed Air: Minimum pressure of 4.83 bar (70 psig) of dry air. 9.5 mm or 6.4 mm (0.38 or 0.25 in) OD tubing. Connections external to machine not supplied by 3D Systems

Configurations Base unit (controller and a printer), scalable to 24 auxiliary printers

Dimensions (WxDxH) Base unit (uncrated): 122.6 x 72.9 x 209.1 cm (48.2 x 28.7 x 82.3 in)

Auxiliary printer (uncrated): 66.1 x 72.9 x 209.1 cm (26 x 28.7 x 82.3 in)

Weight Controller (uncrated): 98.5kg (217.2 Ibs) Printer (uncrated): 190.5kg (420 Ibs)

Certifications FCC, CE, EMC, UL

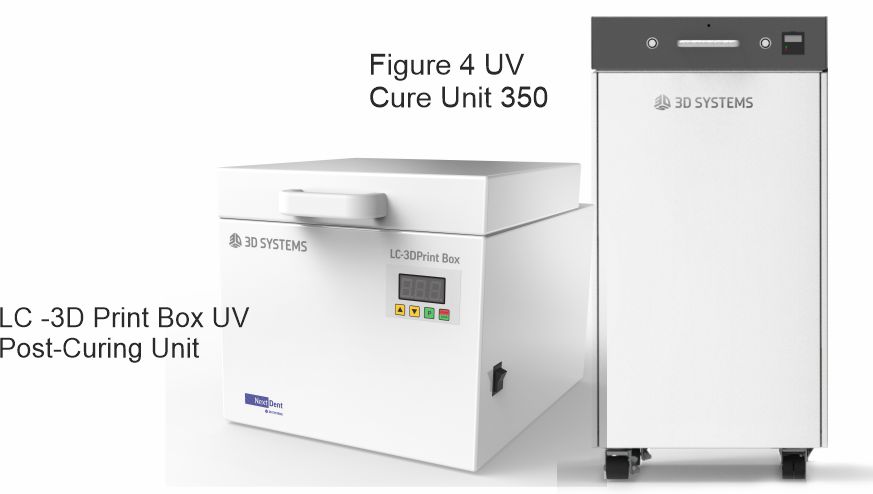

LC-3DPRINT BOX UV POST-CURING UNIT

The LC-3DPrint Box is available for UV-curing parts and is the recommended UV-curing unit for Figure 4 Modular print materials for parts under 195 mm. The LC-3DPrint Box is a revolutionary UV light box equipped with 12 UV light bulbs strategically placed inside to ensure a product is illuminated from all sides, which results in a quick and uniform curing cycle.

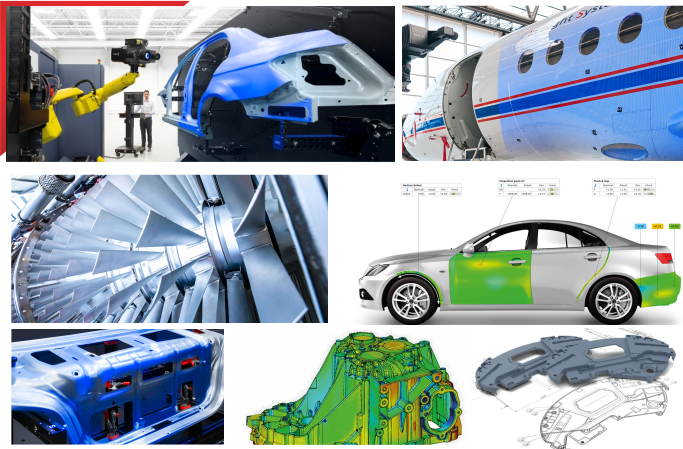

Revolutionizing manufacturing

Scalable, semi-automated 3D manufacturing solution designed to grow with your prototyping and production needs. Enabling companies to move directly into production from digital CAD files to delivering final parts immediately. Speed and versatility Same-day prototyping and direct 3D production up to 10,000 parts per month. In addition, each printer can run different materials and different jobs as part of a single high throughput line serving a multitude of parts being produced

Speed and versatility

Same-day prototyping and direct 3D production up to 10,000 parts per month. In addition, each printer can run different materials and different jobs as part of a single high throughput line serving a multitude of parts being produced.

© 2022. APM Technologies 3D Pvt Ltd

Copyright © 2022. All rights reserved