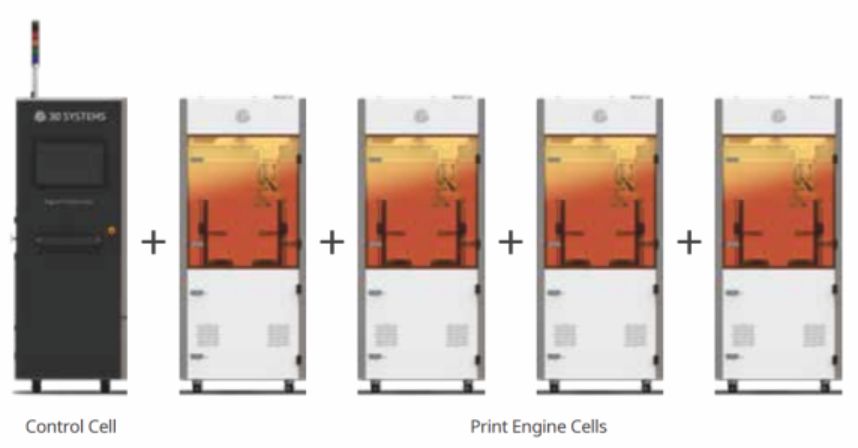

Rigid Material

Figure 4 rigid materials produce durable plastic parts with the look and feel of cast urethane or injection molded parts, with features that include fast print speeds, higl elongation, exceptional impact strength, humidity/moisture resistance, long-term environmental stability and more.

Elastomeric Materials

Figure 4 elastomeric materials are ideal for the production of functional rubber-like parts with excellent shape recovery, high tear strength, great for compressive applications and material malleability

High Temperature Material

With heat deflection temperatures up to over 300°C with no additional thermal post-cure required, Figure 4 heat resistant material offers high rigidity and exceptional stability under extreme conditions. .

Speciality Material

Figure 4 Production is compatible with 3D Systems' entire portfolio of NextDent materials to facilitate full customization of dental devices. You can also choose from Figure 4 specialty materials for sacrificial tooling, jewelry casting, medical applications requiring biocompatibity and/ or sterilization, and more.

© 2022. APM Technologies 3D Pvt Ltd

Copyright © 2022. All rights reserved