Customer login

Not registered yet?

Register now! It is easy and done in 1 minute and gives you access to special discounts and much more!

Q Pro

- Home

- Q Pro

Q Pro

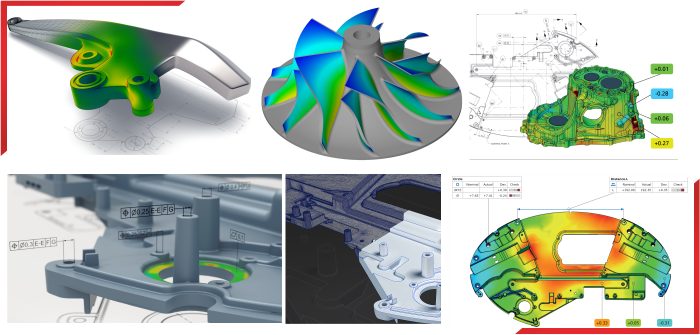

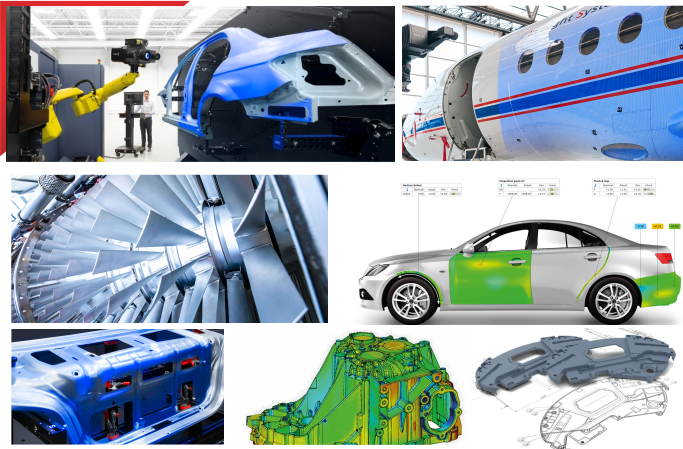

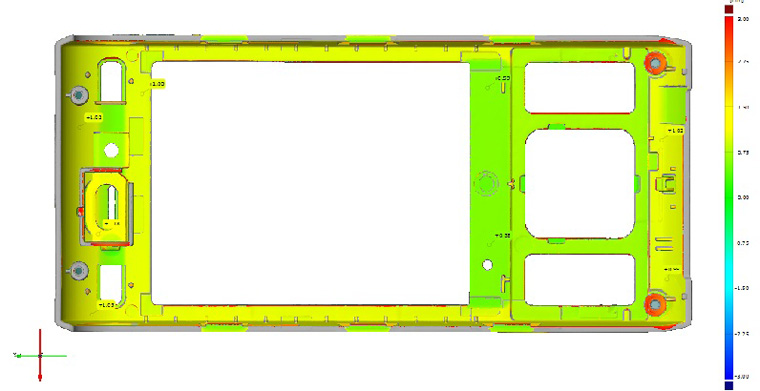

Standard Reports are for inspection

Q-Pro reports are analysis

"Q-Pro reports are detailed inspection reports which explain more than a deviation color plot. Standard reports offers only color plot of part deviation w.r.t CAD CAD is now a necessity in component development and the practice of achieving prototypes close to CAD requires same level of inspection as well. We are taking inspection to next level through thorough analysis of components by analyzing micro to macro features and parameters which may affect the quality, performance and productivity.

Q-Pro reports consists following analysis tools

3D Printing / Caming from your CAD files- APM offers 3D printing from you CAD files an high resolution hmachine MJP-3600 Max to offer you unmatched quality of output.

3D printing from existing parts by 3D Scanning - APM has the capability to generate STL CAD file from your existing parts or patterns which can their be printed for replication. Also sizing can be easily done or scanned parts to prints patterns in various size.

3D Scanning of existing parts - APM can scan & generate dedicated STL file from existing pattern which can be used for

© 2022. APM Technologies 3D Pvt Ltd

Copyright © 2022. All rights reserved