Customer login

Not registered yet?

Register now! It is easy and done in 1 minute and gives you access to special discounts and much more!

Figure 4 Standalone

- Home

- Product

- Figure 4 Standalone

Highlight

Direct Digital Print

Feature

3D Technology

Applications

Prototyping

Fast, Precise, Versatile

Figure 4 Technology

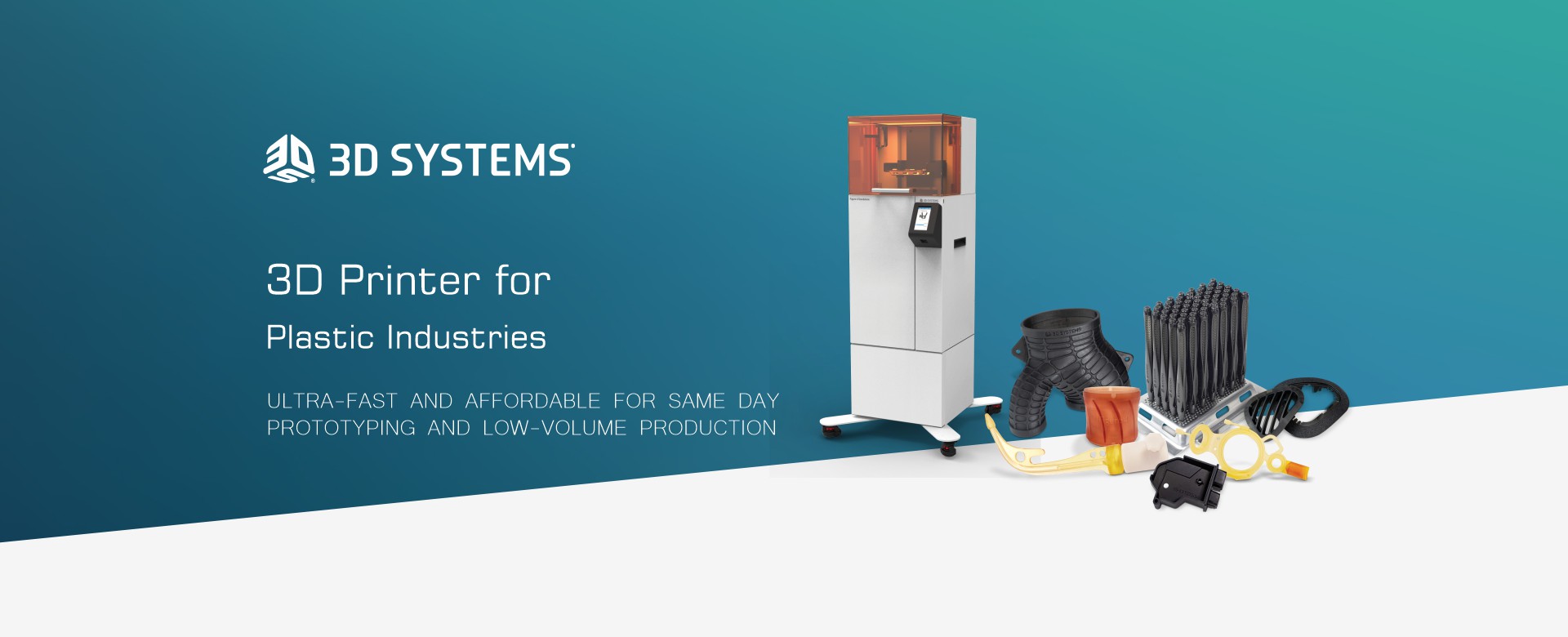

New Levels of Speed and Production Capability

Figure 4® delivers ultra-fast additive manufacturing technology with systems that offer the expandable capacity to meet your present and future needs. With access to a range of innovative materials, Figure 4 enables tool-less alternatives to traditional injection molding or urethane casting processes with direct digital production of precision plastic parts, as well as same-day rapid prototyping.Achieve same-day functional prototyping and low volume production, with ultra-high speeds. Figure 4 offers quality and accuracy with industrial-grade durability and service, and 3D Connect® for proactive and preventative support.Figure 4 includes 3D Sprint®, aneasy-to-use advanced print management software. Streamline your file-to-part workflow, from preparing andoptimizing CAD data to managing the additive manufacturing process.Create parts that combine high resolution with exceptional surface quality and mechanical properties from a variety of robust, production-grade and biocompatible-capable materials. Production-Grade MaterialsEase of UseFast Turnaround

FIGURE 4 STANDALONE

Affordability

Part of 3D Systems' scalable, fully integrated Figure 4' technology platform, Figure 4 Standalone is an affordable and versatile solution for low volume production, and same-day prototyping for fast design iteration and verification, offering speed, quality, and accuracy with industrial-grade durability, service, and support. With a compact and easy-to-use design, Figure 4 Standalone delivers industrial-grade durability at an affordable price and low total cost of operations.

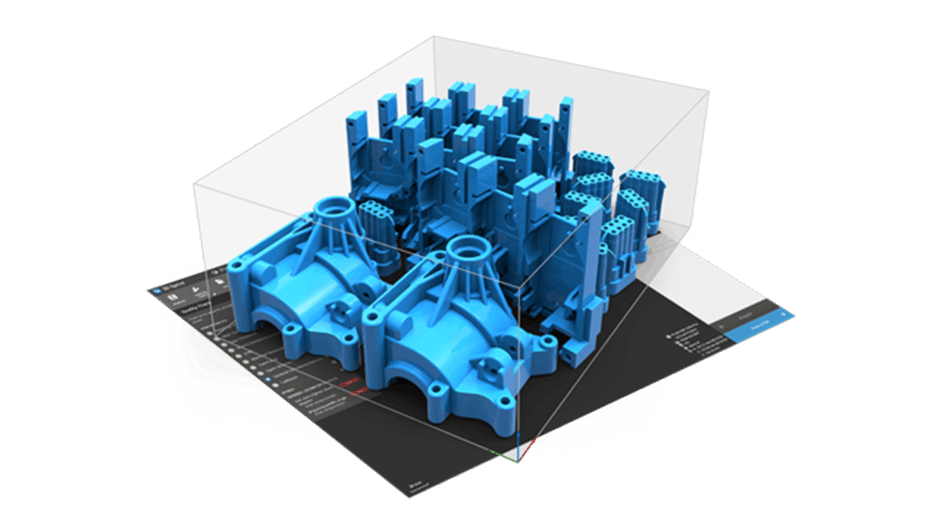

Versatility

Quick and easy material changeover allows for functional prototyping and production application diversity with the same printer. Featuring a manual material feed, it is augmented with separate post-processing units available for cleaning, drying, and curing.

Fast Turnaround

Achieve same-day functional prototyping and low volume production with ultra-high speeds. Figure 4 Standalone offers quality, accuracy, and Six Sigma repeatability (Cpk > 2) with industrial-grade durability, service, and support. Figure 4 Standalone was designed for ease-of-use and includes file preparation and print management with 3D Systems 3D Sprint software.

Broad Range of Materials

Broad Range of Materials 3D Systems’ Material Design Center has over 30 years of proven R&D experience and process development expertise. The broad and expanding range of materials available for Figure 4 Standalone addresses a wide variety of applications needs, for functional prototyping, direct production of end-use parts, molding and casting, and includes rigid and durable with thermoplastic-like behaviors, rubber-like, castable, heat resistant, and biocompatible capable materials.

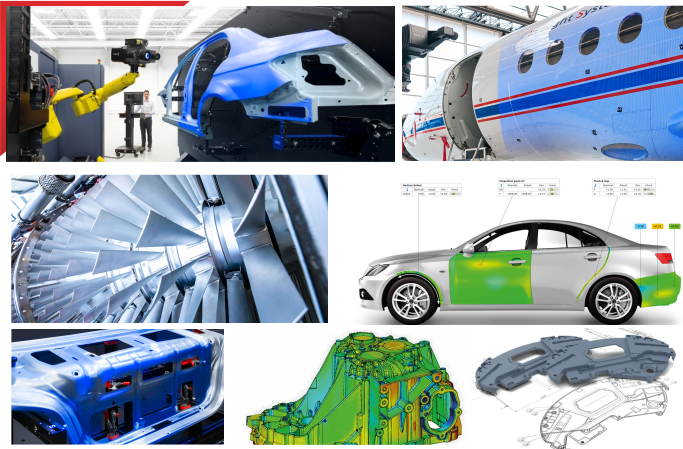

Some Applications

Replacement of traditional molding and cast urethane processes

Rapid functional prototyping and fast concept models

Investment casting patterns for jewelry

End-use durable plastic parts

Short run production of plastic articles

Jigs and fixtures

Rapid tooling -molds and master patterns

Medical applications requiring biocompatibility and/or thermal resistance

Benefits

Affordable initial investment

High throughput vs. competitive 3D printing technologies

Industrial-grade durability

Print and use same day

Low total cost of operations

Application flexibility

Efficient design iteration

Six Sigma quality and repeatability

Printer Hardware

Build Volume (xyz): 124.8 x 70.2 x 196 mm (4.9 x 2.8 x 7.7 in)

Resolution: 1920 x 1080 pixel

Pixel Pitch 65 microns (0.0025 in) (390.8 effective PPI)

Wavelength: 405 nm

Operating Environment

Temperature: 18-28 ºC (64-82 ºF)

Humidity: 20-80%

Electrical 100-240 VAC, 50/60 Hz, Single Phase, 4.0A

Dimensions (WxDxH)

3D Printer crated 73.66 x 68.58 x 129.54 cm (29 x 27 x 51 in)

Pedestal crated 82.55 x 79.375 x 55.245 cm (32.5 x 31.25 x 21.75 in)

3D Printer uncrated 42.6 x 48.9 x 97.1 cm (16.7 x 19.25 x 38.22 in)

3D Printer + Pedestal uncrated 68.1 x 70.4 x 135.6 cm (26.8 x 27.71 x 53.38 in)

Weight

3D Printer crated 59 kg (130 lbs)

Pedestal crated 26.3 kg (58 lbs)

3D Printer uncrated 34.5 kg (76 lbs)

3D Printer + Pedestal uncrated 54.4 kg (120 lbs)

Certifications FCC, CE, EMC

Accessories

LC-3DPRINT BOX UV POST-CURING UNIT

The optional LC-3DPrint Box post-curing unit is available for UV-curing parts, required to obtain the final material properties, and is the recommended UV-curing unit for Figure 4 Standalone print materials. The LC-3DPrint Box is a revolutionary UV light box equipped with 12 UV light bulbs strategically placed inside to ensure a product is illuminated from all sides, which results in a quick and uniform curing cycle. This light-based UV curing process takes minutes versus hours with heat-based curing processes.

LC-3DMixer from 3D systems

The optional LC-3DMixer keeps your Figure 4 materials ready for use at any time at an ottimum consistency . The LC -3D Mixer is rolling/tilting stirring device for mixing 3D printing materials

© 2022. APM Technologies 3D Pvt Ltd

Copyright © 2022. All rights reserved