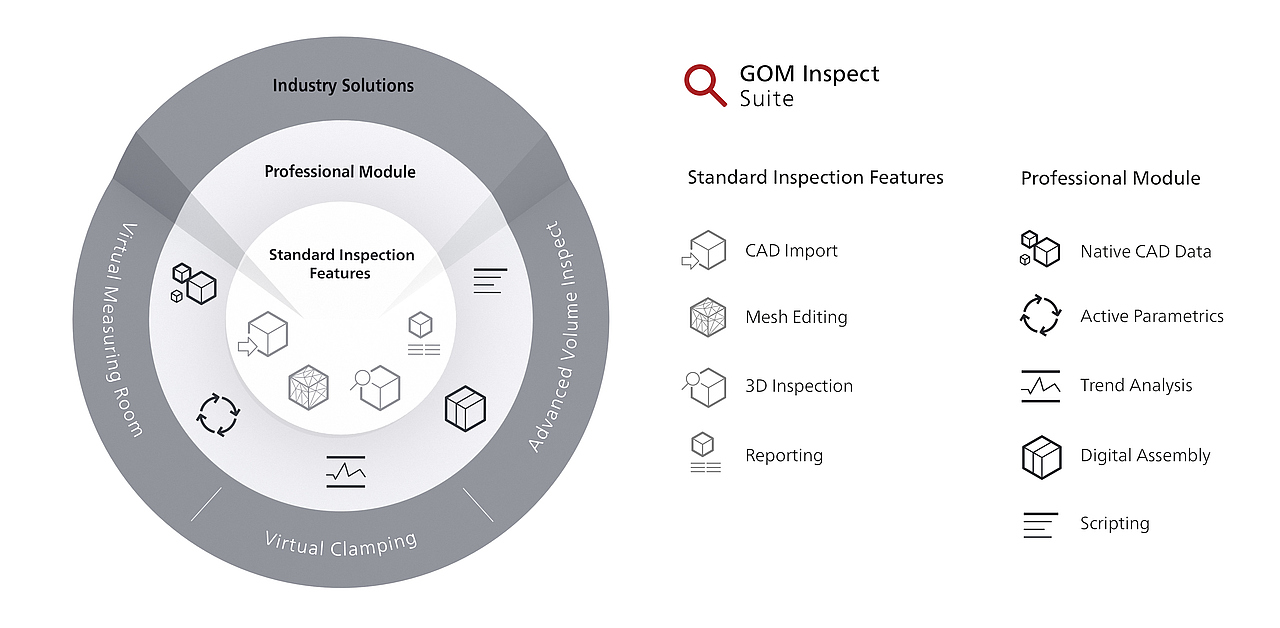

Measuring data – independent of the system CAD data

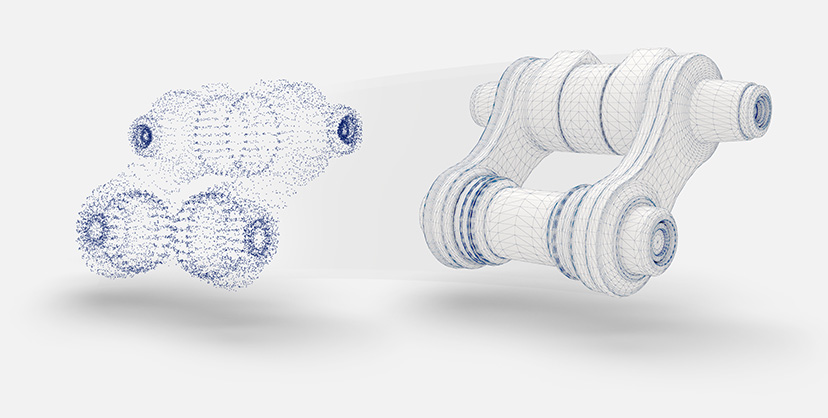

Data Import

Mesh Processing

From point clouds to polygon meshes Suitable for reverse engineering and 3D printing

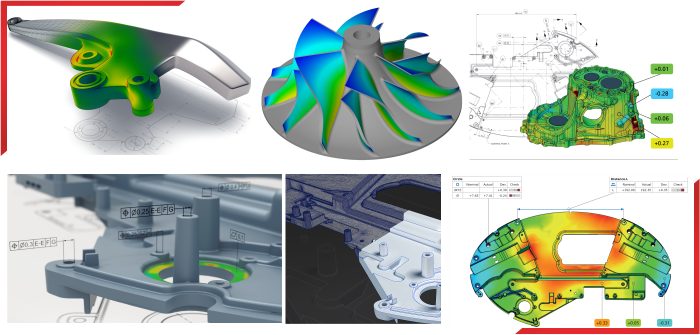

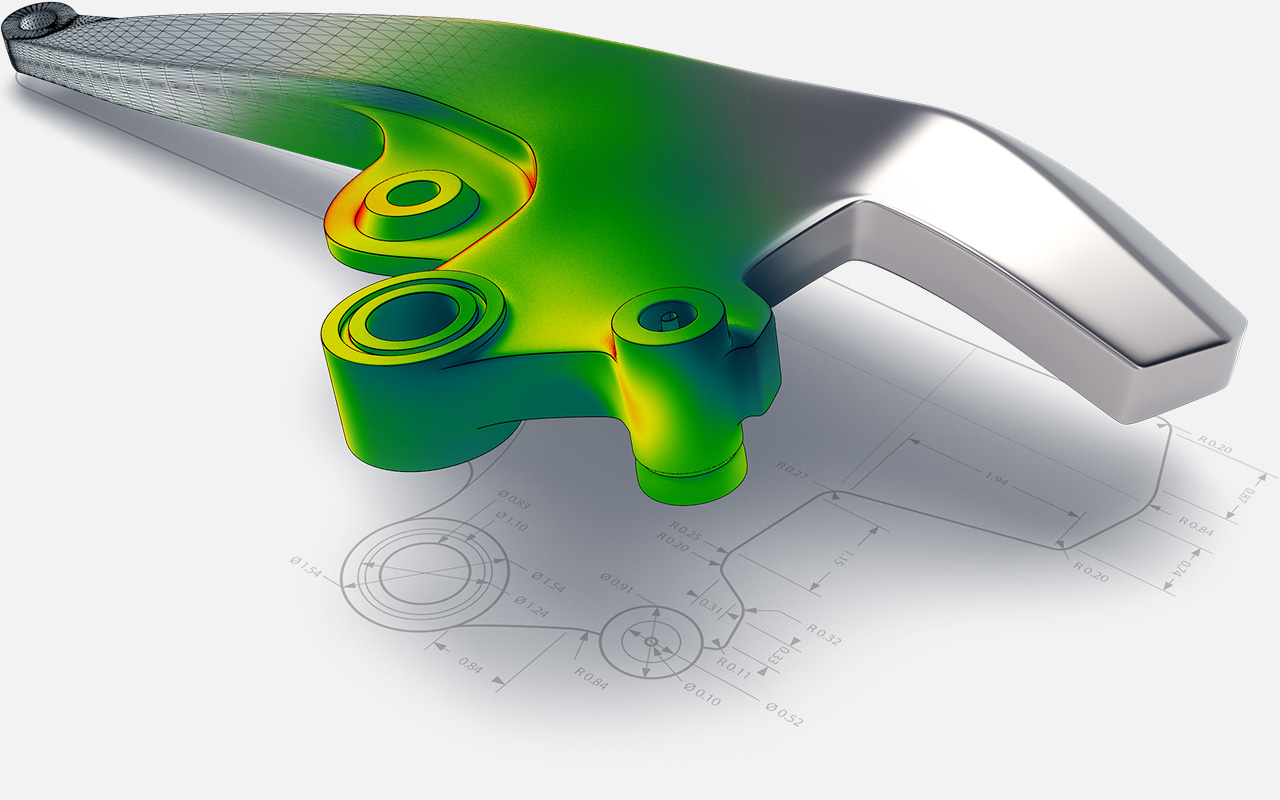

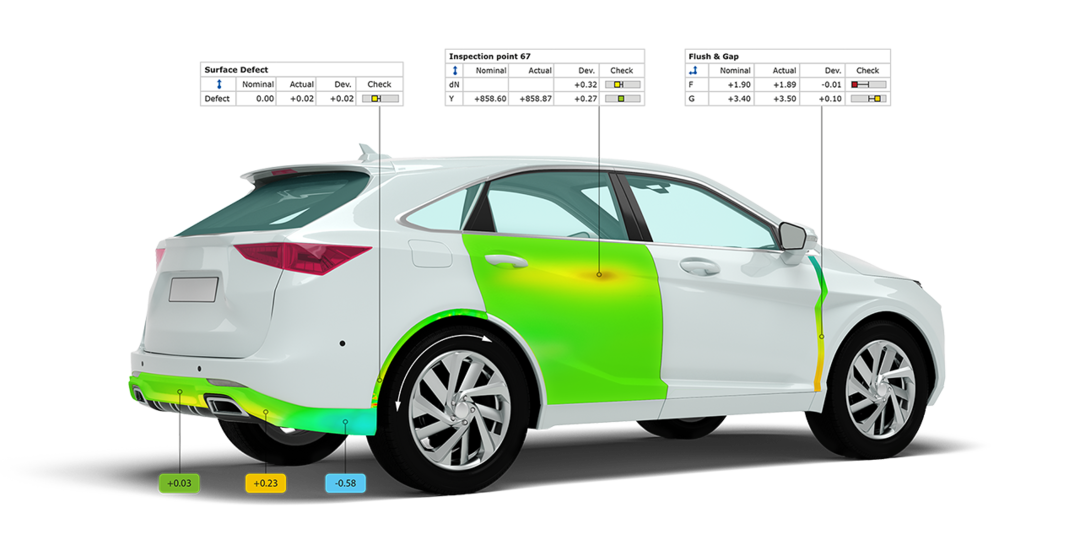

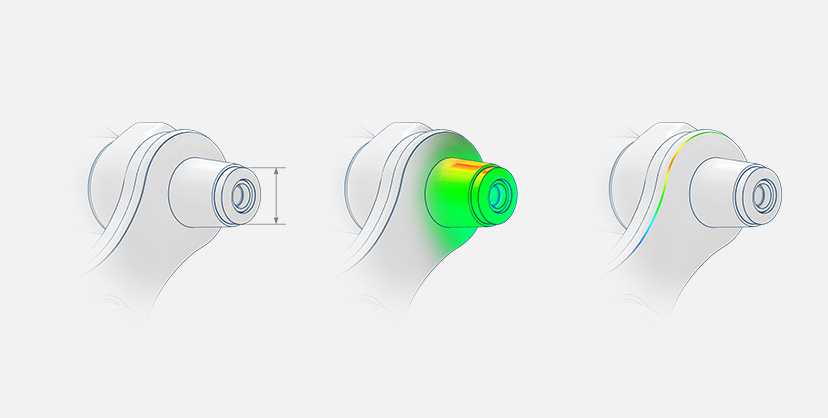

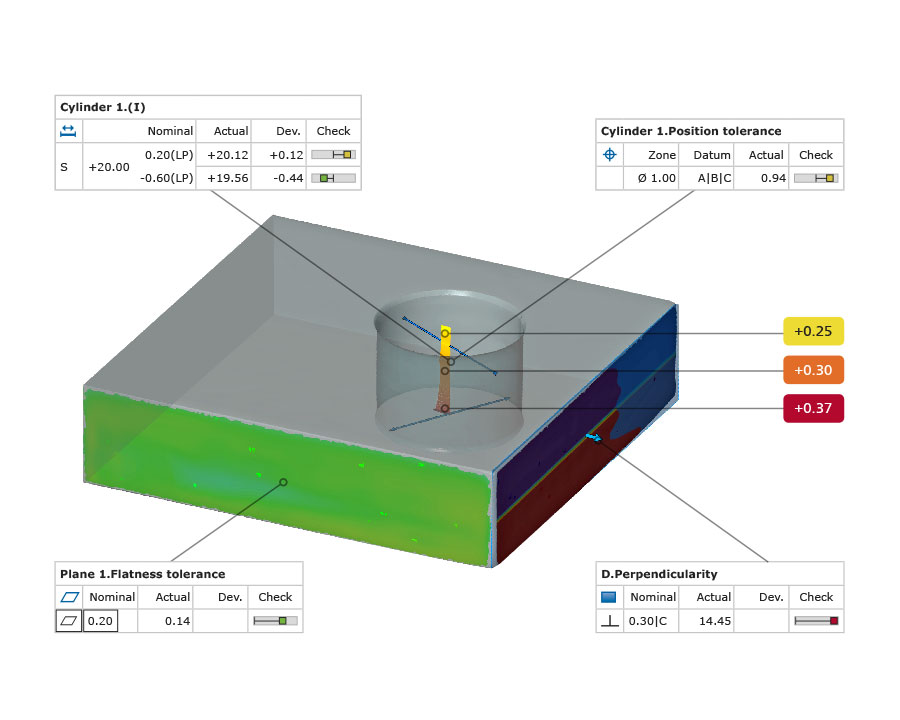

Inspection and Evaluation

Points, surfaces and curves according to standard requirements

Industry-specific Analysis Tools

e.g. for sheet metals, cast parts, plastics and airfoil inspection

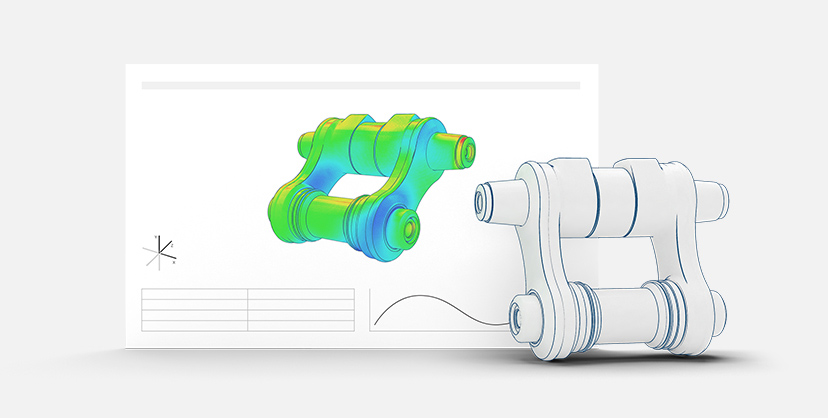

Reporting Functions

For all common process and data standards Export as PDF

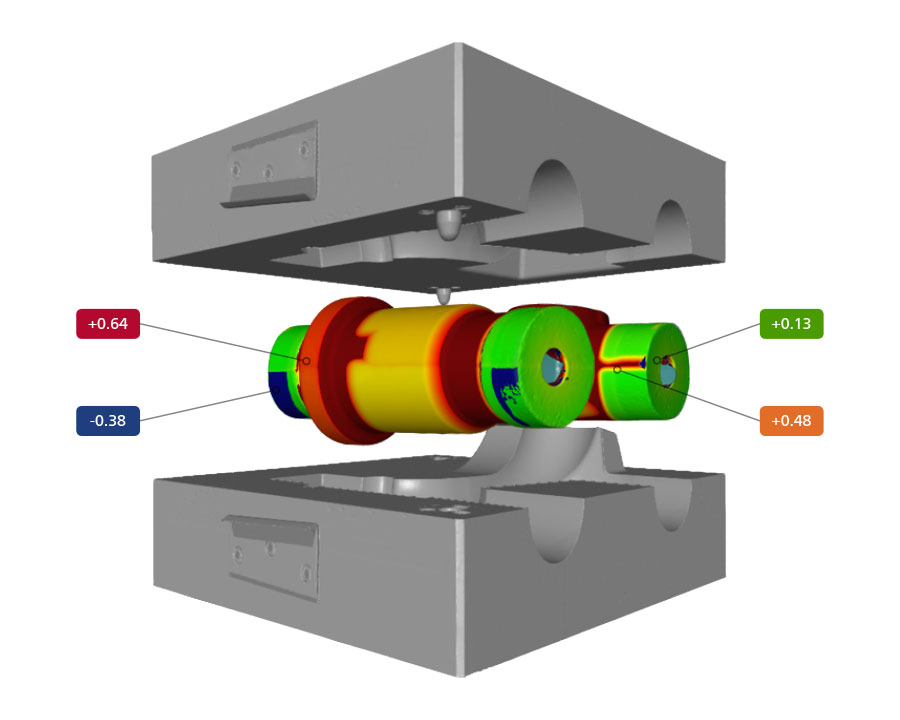

Digital Assembly

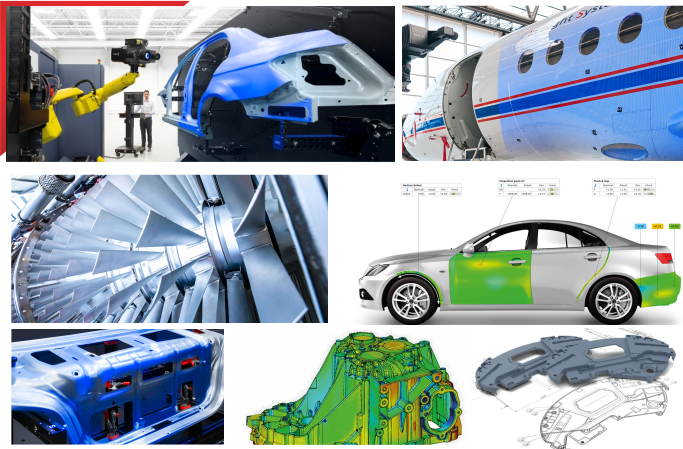

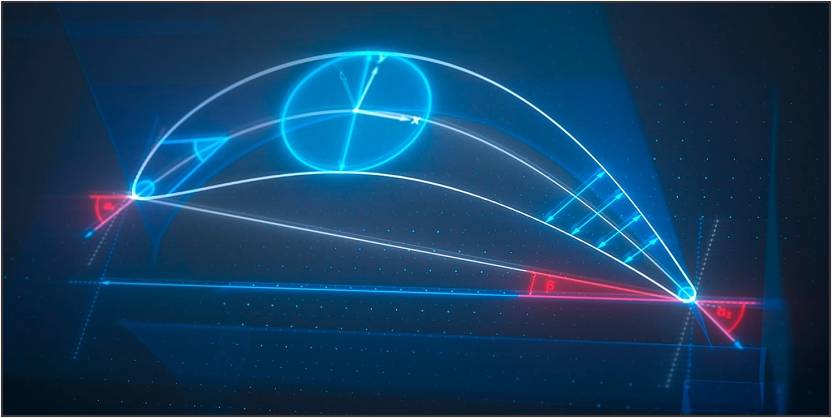

Blade Inspection

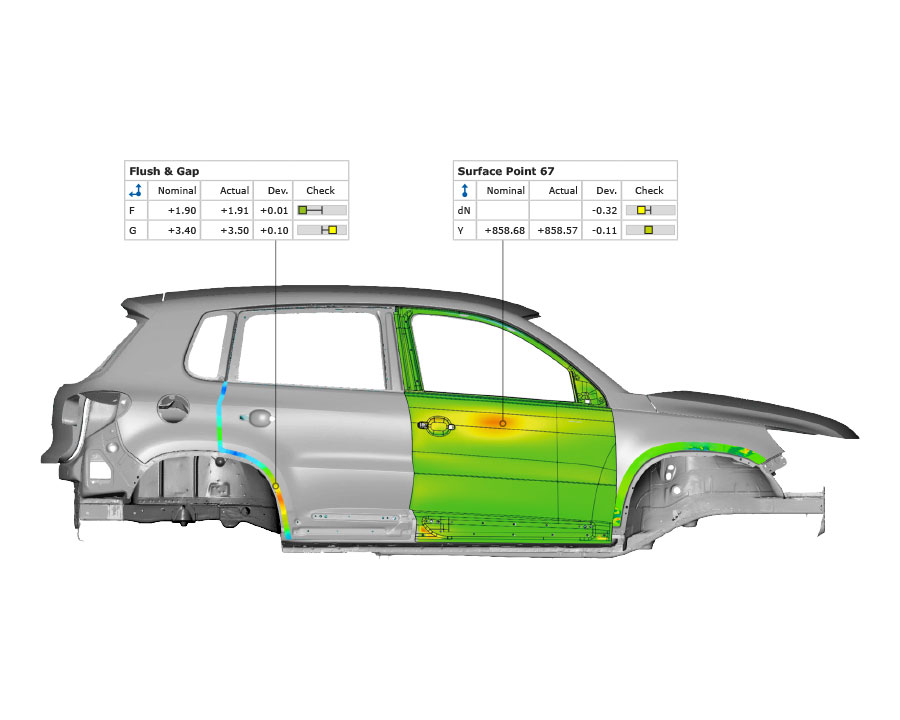

Next Steps in Automotive Car Body Inspection

Smart Inspection

© 2022. APM Technologies 3D Pvt Ltd

Copyright © 2022. All rights reserved