Sheet Metal Forming

Optical Measuring Technologies in Sheet Metal Processing

K. Galanulis (GOM, Germany) May 2005

This paper presents three optical measuring technologies which became a part of sheet metal forming in many industrial applications during the past years.

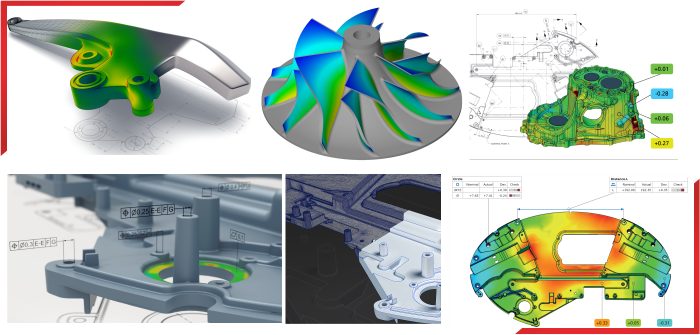

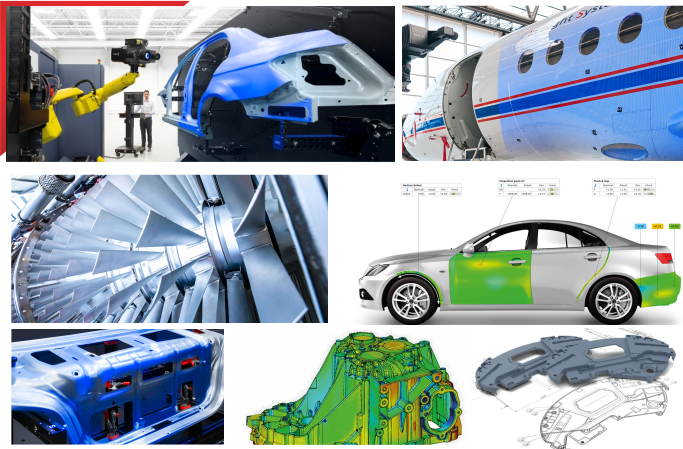

Digitizing by ATOS provides the geometrical information of the complete shape of parts. This technology is mainly used in the automotive industry in reverse engineering, analysis and quality control applications, like first article inspection, assembly control, tool manufacturing and optimization, production monitoring and incoming components inspection.

Forming analysis by ARGUS delivers the full field distribution of major and minor strain, the thickness reduction as well as the forming limit diagram for stamped metal sheet parts. The main applications include the verification of numerical simulations, the fast and robust evaluation of forming processes in the stamping area. In a further stage of system expansion, material properties like forming limit curves or flow curves can be determined accurately and independently of the operator.

The main advantages of these relatively new technologies are:

The importance of these technologies will increase in the future as they improve the time compression of the part and its production development, and reduce the feedback time of production monitoring.

© 2022. APM Technologies 3D Pvt Ltd

Copyright © 2022. All rights reserved